16MM micro coreless gear motor, high torque, long life, replace maxon.

Precision high torque planetary gearbox, high efficiency and low noise, low backlash design, achieves high positioning accuracy, suitable for high speed, high frequency and reverse running applications to make your drive more powerful, more precise and more reliable!

16MM Coreless Planetary Gear Motor,add encoder, It is a non-contact high-speed, high-precision magnetic encoder that uses the Hall principle. The Hall sensing point array is built into the center of the chip, and generates sine and cosine position signals by sensing a pair of magnetic poles on it. This encoder is suitable for various harsh environments (the encoder output response is 8, 16, 32, 64, 128, 256, 512, 1024,2048PPR, etc., supporting up to 20000 RPM). Shenzhen Micro Planetary Gearbox-Focus on micro precision transmission systems, core components of robot hands, instrument coreless motors, medical gear motors

Encoder drawing:

Encoder output:

Coreless Gear Motor Series Introduction

Precision high-torque planetary gearbox, small size, high torque, long life!

Adopt customized structural design to achieve high efficiency and low noise;

Using stainless steel and special heat treatment process to ensure the wear resistance and strength of the gear;

The low backlash design achieves high positioning accuracy and is suitable for high-speed, high-frequency and reverse operation applications;

Diameters range from 6mm to 42mm, combined with our various specifications of motors and encoders, to form a precise and compact drive system.

16mm Coreless Gear Motor Introduction

Gearbox properties: Planetary gear

Gear type Hardened: stainless steel

Output shaft: Hardened alloy steel

Sun gear: Hardened stainless steel

Inner ring: Stainless steel

Connection cover: Stainless steel

Output end: bearing Ball bearing

Axial clearance: 0-0.1

Direction: Forward/reverse

Provide customizable precision planetary gearboxes:

Customizable options

Specifications, wire length, shaft length, performance, bearings, gearbox,

Unit price

Quote according to customer customization, quantity and solution requirements

Use miniaturized gearbox transmission design to achieve stable transmission of planetary gears in a limited space, gear efficiency can reach more than 80% per stage, and high-precision processing effectively ensures the smooth operation of the gearbox

Equipped with various brushed and brushless hollow cup motors, adopt a large speed ratio to achieve a small space, high torque output structure to meet the customer's special use environment

Carefully optimize gearbox parameters, such as displacement coefficient distribution, tooth angle optimization, overlap, slip rate and strength enhancement, so as to reduce gearbox operation noise and improve gearbox efficiency and life

Use gears of different materials to enhance the strength and wear resistance of gears, ensure the normal operation of the gearbox when the motor is running, so that the whole machine has a service life of more than 3000 hrs

Advantages of Coreless Motors

Coreless motors have outstanding energy-saving, control and drag characteristics, mainly:

1. Energy-saving characteristics: The energy conversion efficiency is very high, and its maximum efficiency is generally above 70%, and some products can reach more than 90% (iron core motors are generally 20-50%).

2. Control characteristics: Rapid starting and braking, extremely fast response, mechanical time constant is less than 28 milliseconds, and some products can reach less than 10 milliseconds (iron core motors are generally more than 100 milliseconds); under high-speed operation within the recommended operating area, the speed can be easily adjusted sensitively.

3. Drag characteristics: The operating stability is very reliable, and the speed fluctuation is very small. As a micro motor, its speed fluctuation can be easily controlled within 2%.

In addition, the energy density of coreless motors has been greatly improved. Compared with iron core motors of the same power, its weight and volume are reduced by 1/3-1/2.

16MM high torque coreless planetary gear motor pictures 1725R

16MM High Torque Coreless Planetary Gear Motor Product Dimensions 1725R

16MM high torque coreless planetary gear motor parameter table 1725R

NO. |

Model | Volt range | Rated volt | No load speed | No laod current | Stall Torque | Stall Current |

V | V | r/min | mA | mNm | A | ||

1 | KG-16P1725R-V1 | 3-5 | 4.5 | 37 | 57 | 2037 | 3.7 |

2 | KG-16P1725R-V2 | 8-12 | 12.0 | 46 | 46 | 2456 | 2.1 |

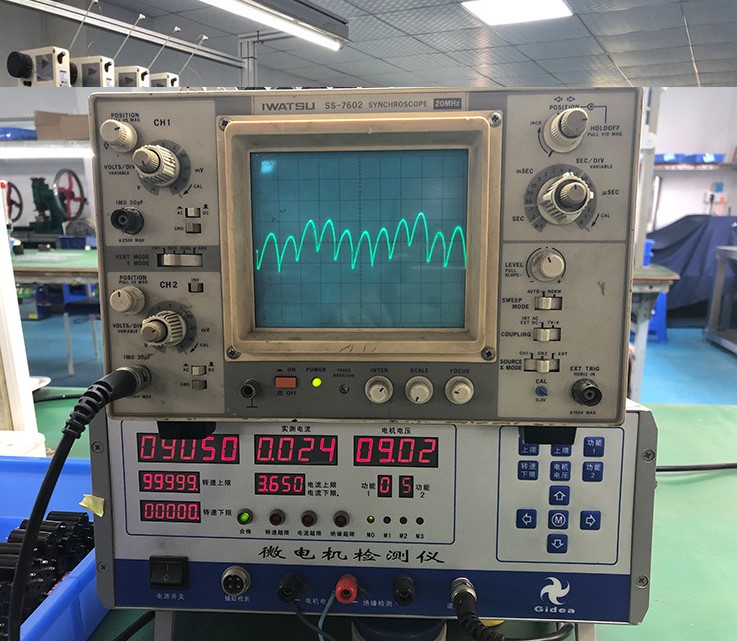

Coreless Motor Production Process

Coreless planetary gear motor production process

Kegu Motor provides precision DC drive overall solutions for various related industries. Our innovative products include coreless DC brushless and brushed motors,Servo drives, planetary gearboxes, encoders and static brakes.

Contact: Hong Kong Kegu Motor Sales Department

Phone: +86-18682260827

Tel: +86-0755-27801762

Email: sales@kegumotor.com

Add: 301, No. 12, Yaming Street, Dongkeng Community, Fenghuang Street, Guangming District, Shenzhen